Continued economic growth is rendering stimulus to industrialization. Over the years, a wide range of industries and sectors have shown tremendous growth, including the manufacturing landscape. Scientific advancement and innovation are facilitating manufacturing industries to obtain best-of-breed industrial cutting technology. Over the years, double pallet fiber laser cutting machines have emerged as significant machines, reshaping the manufacturing ecosystem with their crucial role in metal cutting.

In this manufacturing industry-centric blog, we are going to focus on a wide range of aspects related to laser cutting machine, industrial cutting technology, benefits, etc.

Understanding metal cutting

To begin with, let’s first understand metal cutting. In simple words, metal cutting refers to the removal of unnecessary metal material from a workpiece or job material, enabling it to get a desired shape or form. The process of metal cutting is integral to industries galore, as precise and accurate dimensions are necessitated to meet a specific design or shape.

How does metal cutting take place? The process of metal cutting is implemented by a wide range of methods, including mechanical cutting, thermal cutting, and chemical cutting among others. The choice of cutting method primarily depends on metal, application, and industry.

It’s now time to switch over to the core issue.

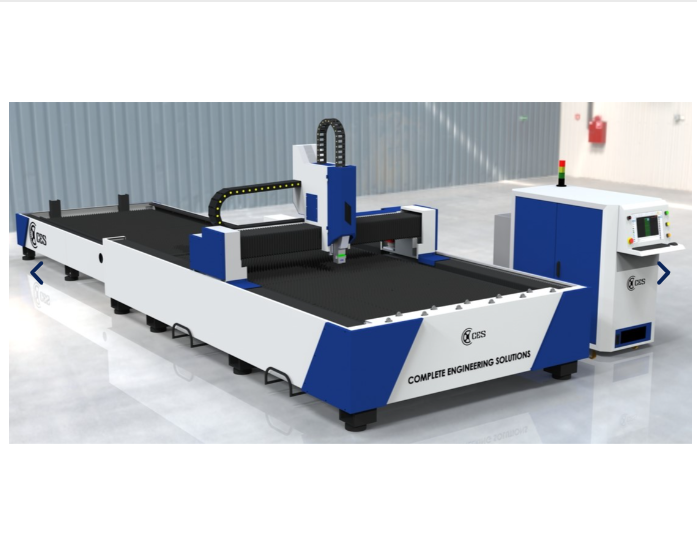

Learning about double pallet fiber laser cutting machines

People directly related to the metal cutting industry would agree that fiber laser cutting is one of the remarkable cutting methods that has emerged in recent times, driven by laser cutting efficiency. What exactly is fiber laser cutting? Is it a complex method, involving plenty of layers within layers? Let’s unfold this puzzle for you.

A fiber laser cutting machine draws benefits from active optical fibers. A laser beam and a transport fiber are created. Subsequently, the former is transmitted to the machine’s head from active optical fibers. Through a defined process, this super-hot laser is condensed, resulting in a narrow beam that is employed to cut metals of different thicknesses.

This modern industrial cutting technology uses a solid-state of laser to melt and pierce different types of metals, leading to precision in dimension and design. Do you know – why is it called fiber laser cutting? The medium for cutting here is optical fiber, therefore it is categorized as fiber laser cutting. Whereas, the entire machine is known as a fiber laser cutting machine.

How do double pallet fiber laser cutting machines work?

According to industry experts, industrial cutting technology machines emit a target-oriented, high-powered laser beam, riding on stimulated radiation. A laser diode produces high-intensity light, which is later transported to the fiber optic cable. Here the beam of light is further intensified.

As and when this high-intensity laser beam is directed to the surface of the material to be designed and fabricated, the high-intensity light beam generated is absorbed. Here the light beam is converted into heat, resulting in melting of the surface. What happens to the molten material? The unwarranted molten material is blown away by a high-speed airflow that runs parallel to the high-intensity laser beam.

Here it makes sense to highlight that the fiber laser’s first hit to the material is relatively more intense than a subsequent hit to the surface of the material. There’s a logic behind that flow. Its role isn’t limited to cutting the surface of the material, in fact, the first hit has to pierce the material. And it can’t be possible unless a high-intensity beam. How long does the beam last? The beam lasts for around ten seconds for a twelve-millimeter sheet of stainless steel. These are some of the working.

Mechanism and medium

What mechanisms and mediums are used in double pallet fiber laser cutting machines? Fiber laser-based cutting machines essentially use a definite set of elements, including erbium, ytterbium, neodymium, or dysprosium. By mixing these elements through a defined process, a crystalline fiber in a solid state is obtained. This crystalline fiber is later guided into the machine cutting head with the help of a transport fiber.

Benefits of using a double pallet fiber laser cutting machine

From the basics, let’s now switch over to the benefits of the terrific machine. Here are the unique benefits of the premium quality double pallet fiber laser cutting machine, driven by the latest Industrial cutting technology:

- Production optimization

- Repeatable process

- Dual interchangeable platforms

- Computerized digital control panel

- Easy to maintain and clean

- Material flexibility

- Fast-cutting speed with low downtime

Production optimization

As the machine has the competency to cut thicker material at a rapid pace, it certainly aids in production optimization. It means there are financial benefits for companies having a high volume of job pieces for laser cutting. On the contrary, CO2-based laser cutting requires close to 10 minutes for warm-up, before they can eventually start operating. That’s the reason, such machines are losing their prominence.

Repeatable process

Unlike traditional and retrograde metal cutting machines that practically offer short-term stability and often suffer from power degradation and efficiency, double pallet fiber laser cutting machines provide efficient performance continuously. Subsequently, the efficiency leads to production optimization.

Dual interchangeable platforms

The premium quality machines demonstrate laser cutting efficiency during application. The presence of dual interchangeable platforms facilitates in loading and unloading of materials. This unique design feature allows a speedy laser cutting process and, at the same time maintains accuracy and precision.

Computerized digital control panel

This is one of the unique features of double pallet fiber laser cutting machines. A computerized digital control panel empowers the operator to control the surface of the material and the pattern and intensity of the laser beam. A computer-enabled design workstation receives the info and data related to cutting the material.

It’s easy to maintain and clean

As a businessman, you seek a machine that requires less maintenance. This machine is ideal for you. It doesn’t require continued replacement of spare parts, thereby reducing the burden and expenses of maintenance to a great extent. Since the technology-driven machine uses nitrogen in its cutting process, it doesn’t clutter the surroundings.

In addition, fiber lasers use nitrogen in their cutting process, allowing for faster, more precise, and less messy cutting.

Material flexibility

Modern industrial cutting technology-based machines are designed and engineered for cutting a variety of materials, including stainless steel, mild steel, aluminium, brass, copper, and galvanized materials.

Fast-cutting speed with low downtime

This is again another unique feature of the modern sheet metal cutting machine. The speed at which the machine cuts and fabricates metals is relatively higher than a host of other modern and conventional technologies.

Industrial use

The advanced metal cutting machine has found applications in a variety of manufacturing industries, sectors, and activities, including mild steel, stainless steel, aluminum alloy, brass, and other kinds of steel; applicable to sheet metal cutting, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts, arts, sculpture, crafts, tool processing, advertising, various metal cutting industries.

How thick material can a machine cut?

Modern fiber laser cutting machines are available in a variety of cutting capabilities. According to industry experts, a standard machine has the competency to cut a metal sheet up to 13 mm thick. Additionally, a high-powered fiber laser machine with 10kw of power can cut mild steel up to 2mm, while stainless steel and aluminium up to 300mm.

As per the requirements of your industry, you can choose the machine. For in-depth information, you can connect with a prominent double pallet fiber laser cutting machines manufacturer in Ahmedabad.

The basic difference between CO2-based laser cutters and fiber laser cutting machines

CO2-based laser cutters and fiber-based laser cutters apply different types of mechanisms to generate and concentrate laser. At the same time, both technique works at a different set of wavelengths, making them suitable for cutting different types of materials.

Can fiber laser-based cutting machines fabricate reflective materials, like brass, aluminium, and copper?

Many people have this perception that since fiber lasers utilize visible light for cutting metal sheets, it’s not a feasible technique for many reflective materials, like brass, aluminium, and copper. It’s not true. Fiber lasers are competent to penetrate even reflective materials.

Conclusion

Considering the benefits of double pallet fiber laser cutting machines for the manufacturing industry, it’s a product worth investing in. With the help of modern machines, metal cutting, art, and craft have become much easier, more precise, and more accurate, resulting in a drastic change in the manufacturing landscape.

Fiber laser cutting has evolved as one of the modern technologies in laser-based cutting technology, resulting in much-needed remarkable speed and accuracy for the metal fabrication industry.

Let’s connect

CES LASER MACHINE PRIVATE LIMITED (CES), headquartered in Ahmedabad, India, is a prominent manufacturer, trader, and exporter of an excellence-driven range of Laser Cutting Machines, including double pallet laser cutting machines! If you are seeking a quality-driven range of laser cutting solutions, then don’t go further!